24hour hotline(WhatsApp) +86 13831107620

HONGDEFA Your Trusted Partner in Grain Milling

Since 1982, Hongdefa has been at the forefront of industrial-grade maize and wheat milling solutions, empowering businesses across 45+ countries to transform raw grains into premium flour. With 100+ machines installed in Kenya and a dedicated Nairobi support center, we combine four decades of engineering expertise with deep-rooted African market understanding.

China Professional Milling Machinery Manufacturing Co., Ltd.

China Professional Mill Manufacturing specializes in delivering precision-engineered milling solutions tailored to meet your industrial demands. With decades of expertise and a relentless pursuit of innovation, we empower global clients with cutting-edge technologies that redefine efficiency and durability.

Our commitment to excellence is reflected in ISO-certified production processes and components that consistently exceed industry standards for performance and longevity.

Backed by a 24/7 global support network and data-driven customization services, we partner with enterprises to transform operational challenges into sustainable growth opportunities.

From compact mills for agro-processing to large-scale industrial systems, trust our turnkey solutions to elevate your productivity while reducing total ownership costs by up to 30%.

ISO9001

CE

SGS

PVOC

Our Products

1

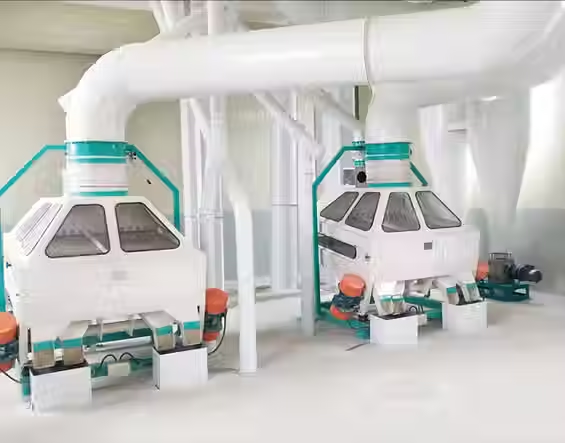

This 240T/24H maize milling machine is a game - changer for large scale processing.

Built with high quality steel, it ensures stable long term operation.

Key features include:

Precision Pneumatic Roller Mills for efficient grinding,

a Japan technology degerminator for pure flour,

and an advanced double sieve for accurate grading.

The touch screen controlled system simplifies operation and offers real time monitoring.

It's also energy efficient, meeting strict environmental standards.

Ideal for big maize processing firms, it boosts productivity and competitiveness.

This 500T/24H maize milling machine in Zimbabwe is a paragon of efficiency and quality.

Engineered to European standards, it features:

high precision components like pneumatic roller mills for thorough grinding. A Japan technology degerminator ensures top notch flour quality. The touch screen control system simplifies operation, allowing for real time monitoring and easy parameter adjustments.

With a robust structure, it can operate continuously, meeting the large - scale maize - processing demands in Zimbabwe and delivering high - quality maize flour consistently.

This 200T/24H wheat milling plant in Zimbabwe revolutionizes large-scale wheat processing.

Constructed with quality materials, it ensures long-term stable operation. Its key features are a cleaning section removing impurities, precision pneumatic roller mills for milling, an advanced sieve for separating flour and bran, and automatic packing options. An easy-to-use control system simplifies operation.

Energy-efficient and compliant with standards, it's perfect for big wheat processors, enhancing productivity and competitiveness.

This 300T/24H wheat milling machine in Afghanistan is a pioneering solution for large-scale wheat processing.

The impact detacher, available in mighty and common types, efficiently pre-grinds kernels, facilitating smoother flour production. The purifier, leveraging self-vibration and blower wind power, secures pure endosperm. Precision pneumatic roller mills for milling. The plansifter, with its unique construction of steel-plate-bent sifter circles, wooden sieve frames, and advanced transmission, precisely classifies materials.

Energy-efficient and compliant with standards, this milling machine, featuring automatic packing and an intuitive control system, is tailor-made for large wheat processors, supercharging productivity and competitiveness.

This is our 5*3000t silo project in Zimbabwe.

Last year, our team attended the opening ceremony. The company, Champion Foods, had previously purchased a 500tpd maize mill and a 200tpd wheat mill from us.

This silo project is another testament to our successful business partnerships and the high-quality equipment we provide.

This is our 3500TX3 silo project in DR Congo

Last year, our team traveled to the DR Congo to conduct after-sales service. During our visit, we also discussed our new business with the client. Our commitment to quality service and product excellence impressed the client, leading them to place a new order with us for 10000T*3 silos.

This not only showcases our strong customer-centric approach but also strengthens our business relationship in the region.

Milling Machine Project

Hongdefa Mill Project in Kenya

"Hongdefa has successfully installed over 150 maize and wheat milling projects across Kenya, including flagship installations in Nairobi (150T/24H), Mombasa (50T/24H), and Kisumu (30T/24H), with 80% of systems operational since 2015 under KEBS certification."

Hongdefa Mill Project in Kenya is transforming the milling industry by providing state-of-the-art technology and training. This initiative aims to enhance the quality of flour production, boost local economies, and create job opportunities. With a focus on sustainability and innovation, the project is poised to make a significant impact on the agricultural landscape in Kenya.

Spare Parts Available

Feedback from Our Clients

Payment Accept

Our Flour Milling Projects in different countries

We prioritize clients' core needs and continuously optimize key service standards to deliver exceptional value.

Kenya

Zambia

Ethiopia

Uganda

South Africa

Zimbabwe

Tanzania

Rwanda

Angola

Nigeria

Malawi

DR Congo

Mozambique

Egypt

Namibia

Cameroon

Mali

Ghana

Benin

South Sudan

Swaziland

Djibouti

Burundi

Algeria

Burkina Faso

Côte d'Ivoire

Somalia

Togo

Senegal

India

Thailand

Afghanistan

Malaysia

Mongolia

Sri Lanka

Brazil

Argentina

USA

Venezuela

Uzbekistan